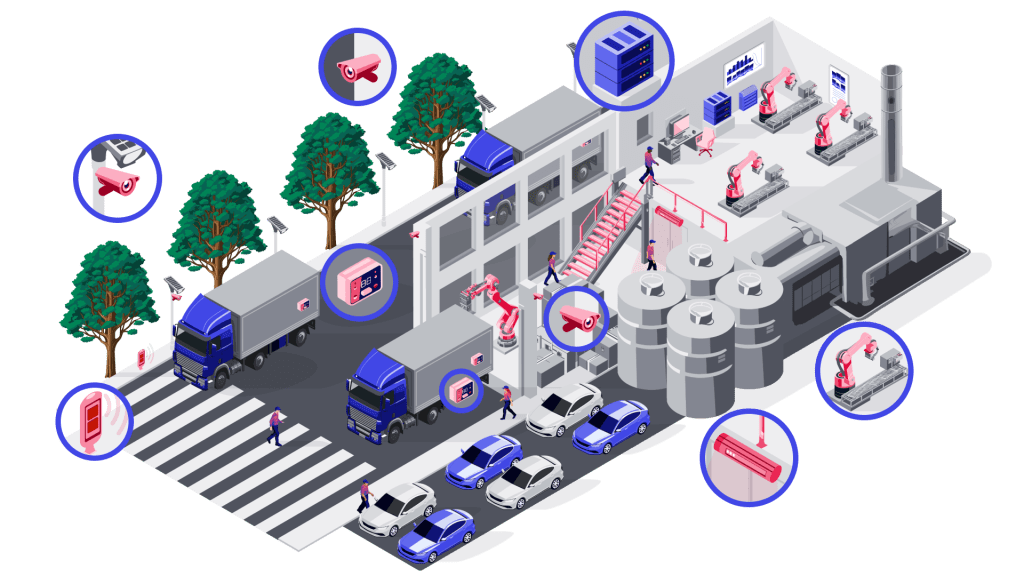

Edge Application Management in Industrial and manufacturing

Your factory floor edge.

The recent snowballing growth of decentralized data collection from IoT applications has led to a massive use of applications in industrial environments.

Avassa empowers industrial operators to bridge the gap between containerized industrial applications and distributed on-site infrastructure. With our application orchestration platform, we enable industrial operators to manage the lifecycle of on-site container applications efficiently, securely, and at the speed of software.

By 2023, at least 75% of “greenfield” IoT projects will use containers for application life cycle management at the edge, up from 30% in 2021. — Gartner, “Market Guide for Edge Computing Solutions for Industrial IoT”

- Application autonomy for non-stop operations and blazing-fast data processing

- Built for low bandwidth and resilient for periods of complete outages

- Declarative deployments and upgrades of containerized applications

- Remote management, installation and onboarding of new on-site locations using an agent with a small footprint

- Automatic discovery of devices such as cameras or GPUs

- Automated placement of applications based on device and GPU availability

- Comprehensive overview and control of which applications run in which on-site location

- Edge-native monitoring and observability

Customer Testimonial

Example Use Cases in Industrial Manufacturing

- Predictive Maintenance and Machine Monitoring: Avassa can be used to deploy and manage applications that monitor the health and performance of manufacturing equipment across various locations. These applications can analyze data locally to predict maintenance needs, reducing downtime and extending the lifespan of machinery.

- Quality Control and Inspection: The platform can support applications that perform real-time quality checks and inspections on the production line. By processing data on-site, manufacturers can quickly identify and address quality issues, ensuring product standards are consistently met.

- Supply Chain and Inventory Optimization: Avassa can manage applications that track and optimize inventory levels and supply chain processes across multiple manufacturing sites. Local data processing allows for real-time responses to inventory changes, helping to avoid stockouts or excess inventory and improving overall supply chain efficiency.

- Energy Management and Operational Efficiency: The platform can be used to control and monitor applications that manage energy usage and other resources in manufacturing facilities. By processing this information locally, facilities can optimize energy consumption and operational efficiency, leading to cost savings and reduced environmental impact.

- Safety and Compliance Monitoring: Avassa can deploy applications that continuously monitor safety conditions and compliance with regulatory standards across manufacturing sites. Local data processing enables immediate responses to potential safety hazards or compliance issues, enhancing worker safety and regulatory adherence.

Reach out

Interested in learning more about our technology?

Send us a message and we’ll let you know how we can help.