Software-Defined Industrial Automation: Transforming Manufacturing with Edge Computing

The landscape of industrial automation is undergoing a transformative shift, moving from traditional hardware-bound systems to software-defined architectures. Software-defined industrial automation refers to a new paradigm where software takes the central role in controlling, optimizing, and managing industrial processes. This shift enables a higher degree of flexibility, scalability, and integration with modern digital technologies compared to legacy systems.

Historically, industrial automation has been dominated by proprietary and closed systems like SCADA (Supervisory Control and Data Acquisition) systems and physical PLCs (Programmable Logic Controllers). These technologies have provided reliable, though limited, capabilities. However, in today’s rapidly evolving digital era, where agility, innovation, and seamless integration with cutting-edge software technologies are paramount, these legacy systems are no longer sufficient.

This paper explores how next-generation industrial automation solutions are moving from hardware-bound, vendor-specific systems to open, flexible, and software-defined architectures. This transformation is paving the way for the future of Industry 4.0, where automation is increasingly driven by software, allowing greater customization, faster innovation, and a more streamlined production process.

The Challenges of Legacy Industrial Automation Systems

Industrial automation systems, as we know them, are largely constrained by closed architectures encapsulated within proprietary hardware. At the heart of these systems are bundled, physical PLCs, which, while robust, lack the flexibility and scalability necessary for today’s advanced manufacturing environments. These closed systems often rely on vendor-specific protocols for sensor data, making integration with rapidly advancing software technologies, such as machine learning and edge computing, difficult and expensive.

One of the biggest challenges manufacturers face with traditional, closed industrial automation systems is vendor lock-in, which limits flexibility and innovation. For example, a large-scale manufacturing plant attempting to implement AI-powered predictive maintenance found itself constrained by proprietary PLCs that couldn’t seamlessly integrate with modern analytics tools.

The result? Costly workarounds and inefficiencies that negated the benefits of AI-driven insights. Similarly, another factory looking to scale its operations struggled with high hardware costs, as its legacy automation infrastructure required expensive, vendor-specific upgrades rather than allowing a more modular, software-driven expansion. These limitations not only increase operational costs but also slow down the adoption of emerging technologies that could enhance efficiency and competitiveness.

Despite incremental improvements, like faster CPUs and enhanced protocols, the core architecture of PLCs remains stagnant. This creates a challenge when scaling to accommodate resource-intensive tasks, such as running edge AI models. Consequently, manufacturers are left with isolated maintenance burdens and high hardware costs.

Software-defined automation eliminates these constraints by shifting control from rigid, hardware-dependent PLCs to flexible, containerized software solutions. Unlike traditional systems, where changes require replacing physical components or rewriting proprietary logic, software-defined automation enables manufacturers to deploy, update, and scale applications dynamically—without being locked into a single vendor’s ecosystem. This approach mirrors the agility seen in cloud-native IT environments, allowing manufacturers to standardize their operations while rapidly adapting to evolving production needs.

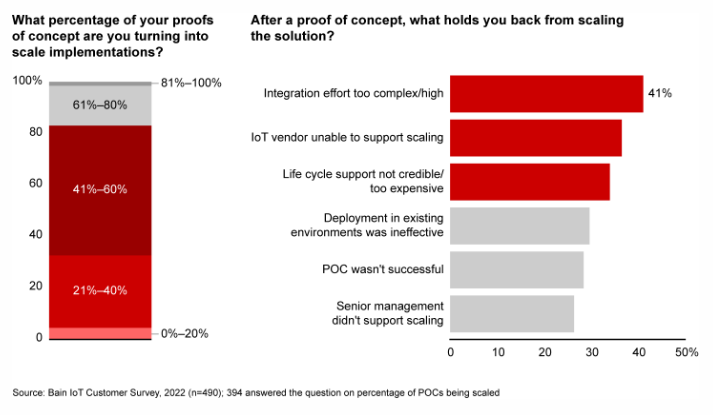

A report from Bain shows that only a small set of the IoT projects are successfully deployed. Major reasons for failure is integration challenges and inability to scale. With open edge compute and modern software technologies these underpinning challenges are addressed to a high degree. A purpose-built edge platform will let you scale the solution across edge environments in the hundreds or even thousands of locations. The report further points out that specifically vendor lock-in is one of the major blocking factors (20%).

Keep Reading: Avassa for Industrial Edge

A Software-Driven Industrial Edge: Disrupting Traditional Automation

Traditional industrial automation relies on rigid, hardware-defined architectures that limit scalability and innovation. By shifting to a software-centric model, manufacturers can overcome these challenges and future-proof their operations.

The future of industrial automation lies in disaggregating the traditional model by adopting a software-centric approach. Virtual PLCs, containers, and edge computing, in combination with commercial off-the-shelf (COTS) hardware, offer a flexible solution that eliminates dependency on proprietary systems. By leveraging open standards and modern software tools, manufacturers can seamlessly integrate machine learning, advanced programming languages, and continuous integration/continuous deployment (CI/CD) pipelines into their automation systems.

Key components of this new architecture include:

- Container-Based Applications: Virtual PLCs and sensor protocol adapters should be containerized to enable flexibility and scalability.

- Open and Flexible Platforms: The adoption of open-edge platforms that avoid vendor lock-in allows businesses to choose their preferred software stack.

- Modern Software Practices: By using mainstream software components, companies can maximize reuse and innovation, reducing costs and improving agility.

This shift enables industrial applications to share infrastructure, cutting down on hardware costs and allowing greater customization and control over the production environment.

A report from reportsandmarkets.com shows that software based automation can significantly reduce errors, save time and money, and accelerate time-to-market by up to 50% and commissioning time by up to 60% compared to traditional approaches.

Industrial Edge Computing: Bringing Intelligence to the Shop Floor

The first generation of industrial applications have used cloud or enterprise data centers to centralize data processing and analytics. Data collected from the shop floor, including sensor readings and machine telemetry, is often sent to cloud or the data center systems for analysis. However, relying solely on the central component can introduce significant challenges, particularly around latency data overload and autonomy.

A crucial benefit of moving away from cloud-centric architectures is enabling real-time intelligence directly on the shop floor. By processing data locally at the edge, manufacturers can reduce latency and handle large volumes of sensor and video data without overwhelming central systems. Moreover, this local processing improves security, as sensitive data can be kept within the factory without the risk of exposure to the cloud. In a world where agility is paramount, the ability to deploy new AI models and applications quickly becomes a key differentiator, allowing manufacturers to stay ahead of the curve.

Four major benefits of Software Defined Automation are:

- Resiliency: With edge technologies you can perform independent software upgrades without restarts and local edge clusters enables application availability.

- Scalability: Adding compute power to the edge is as simple as plugging a cable without iterations to a specific vendors and replacements. The edge platform will enable scalable rollouts across the edge locations.

- Flexibility and extensibility: New features can be added by deploying containerized applications, Edge AI models in an automated pipeline. This in contrast to wait for the PLC vendor to provide it.

Edge AI specifically enables benefits like:

- Predictive Maintenance: Detect machine failures before they occur.

- Quality Control: AI-powered cameras analyze defects in real-time.

- Optimization: Real-time feedback loops can optimize the production.

- Safety functions: Threats can be efficiently detected and personnel notified.

Key Takeaways: The Future of Industrial Automation Platforms and Edge Computing

The industrial automation sector is at a crossroads. The traditional, closed systems that have served the industry well for decades are now outdated and ill-equipped to meet the demands of modern manufacturing. To stay competitive in the Industry 4.0 era, companies must embrace open, software-driven solutions. By leveraging virtual PLCs, containerized applications, and edge computing on COTS hardware, manufacturers can not only reduce costs but also drive faster innovation. This new approach allows for greater flexibility, enhances local processing, reduces reliance on the cloud, and integrates cutting-edge technologies like machine learning directly on the shop floor. The future of industrial automation is one that is open, flexible, and driven by the power of modern software.

How manufacturers can transition to software-driven automation

- Assess Current Infrastructure: Identify limitations of existing PLC-based systems.

- Adopt a Hybrid Approach: Gradually integrate edge computing while maintaining critical cloud functions.

- Invest in AI and Machine Learning: Leverage intelligent automation for predictive maintenance and quality control.

As industrial automation evolves, manufacturers who embrace software-defined, AI-powered systems will lead the way in efficiency, flexibility, and innovation. The shift toward intelligent edge computing is not just a technological upgrade—it’s the foundation for the next era of smart manufacturing.

Checklist for Moving from Legacy Systems to Modern Industrial Edge Computing with Avassa

- Assess Current Systems and Define Objectives: Identify limitations of legacy systems, lockin situation, and set goals like enhanced agility, security, and remote management.

- Perform a SWOT Analysis: Analyze strengths, weaknesses, opportunities, and threats, considering the benefits of software-defined edge orchestration.

- Evaluate Technological Requirements: Ensure compatibility with containerized workloads, automated deployment, and real-time monitoring at the edge.

- Develop a Comprehensive Migration Strategy: Use a phased approach to shift from centralized infrastructure to a distributed edge-native architecture.

- Introduce the Avassa Edge Platform as a software abstraction layer: Enable CI/CD

- Ensure Data Integrity and Security: Leverage Avassa’s zero-trust security model and governance controls to protect edge workloads.

- Engage and Train Stakeholders: Educate teams on edge workload automation, policy-driven updates, and lifecycle management.

- Conduct Pilot Testing and Iterate: Deploy Avassa’s platform in a small-scale pilot, optimize based on insights, and scale gradually.

- Implement and Monitor the New System: Use Avassa’s real-time observability and remote orchestration to ensure continuous performance and reliability.

Further Insights: CODESYS Tech Talk Featuring Avassa and OnLogic

Get started

Book a demo to learn more

Schedule a demo of the Avassa Edge Platform today to learn more.