Edge Computing in Industrial IoT & Manufacturing: Powering Industry 4.0 Transformation

Empowering industrial IoT and automation with Avassa’s edge computing solutions tailored for manufacturing.

The Role of Edge Computing in Industrial IoT & Manufacturing

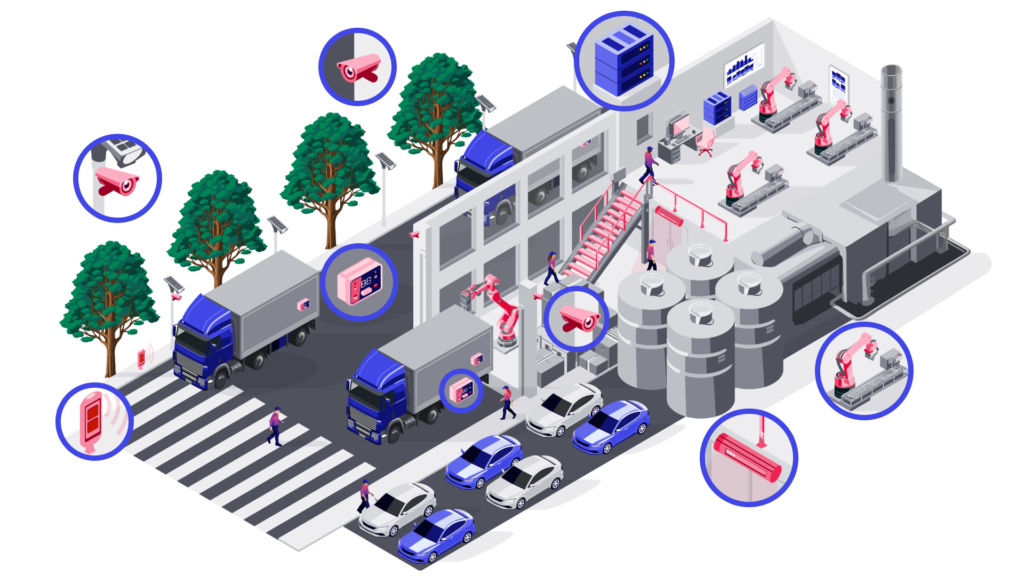

Modern factories are producing more data than ever, with sensors, cameras, and connected machinery generating a continuous stream of information.

Traditional cloud-centric architectures often struggle to keep up—especially in environments where real-time responsiveness, low latency, and high reliability are non-negotiable. Sending every data point to the cloud creates bandwidth bottlenecks, introduces delays, and adds risk in case of connectivity issues.

Edge computing solves this by placing processing power directly on the factory floor, enabling instant decisions, minimizing downtime, and keeping operations running even when the internet doesn’t.

Avassa empowers manufacturers to orchestrate and manage containerized applications and virutal machines across industrial sites—securely, efficiently, and at scale—bringing modern software practices to the edge of industrial automation.

Achieve Operational Excellence with Avassa’s Industrial Edge for Manufacturing

Operational excellence in industrial environments depends on speed, resilience, and control at scale. Avassa helps manufacturers run containerized applications and virtual machines directly at the edge—on the factory floor or in machines—enabling real-time automation, reduced downtime, and streamlined management across all sites. By bringing edge computing to industrial IoT solutions or the factory floor, Avassa gives teams the tools to deploy, monitor, and operate with confidence—even in bandwidth-constrained or offline conditions.

- Non-Stop Production & Real-time Data Processing – In industrial automation, downtime isn’t an option. With edge computing in manufacturing, Avassa enables real-time data processing directly on the factory floor—ensuring critical systems like machine control, predictive maintenance, and quality inspection remain operational even when cloud connectivity is lost.

- Resilient Operations for Low Bandwidth Environments – Many industrial sites operate in environments with limited or unstable connectivity. The Avassa Edge Platform ensures resilient operations by enabling autonomous execution of applications at the edge. Whether you’re managing a single facility or a global fleet, your industrial IoT solutions ensure continued performance regardless of bandwidth constraints.

- Smooth Application Deployment & Management – Managing industrial IoT applications across multiple locations can be complex and error-prone. Avassa simplifies this with a purpose-built platform for the industrial edge. Operators can deploy, update, and monitor containerized workloads across distributed sites, reducing overhead and enabling faster rollouts of new industrial IoT solutions.

- Centralized Control for Distributed Sites – Avassa gives you a single control plane for managing all your industrial IoT applications across geographically distributed manufacturing sites. Our edge platform supports edge manufacturing at scale, letting you monitor and control deployments from one central location—without sacrificing local autonomy or performance.

- Automated Device Discovery & Application Placement – Avassa automatically detects connected hardware like cameras, sensors, and GPUs across your industrial edge. Our edge platform solution intelligently places industrial IoT applications based on available resources, automating deployment and adapts to hardware utilization at every site.

- Edge-Native Monitoring & Observability – Understanding what’s running at the edge is critical for maintaining performance and security. Avassa offers built-in edge-native observability for industrial edge environments, helping you track metrics, logs, and application status across all your manufacturing sites with full transparency.

Seamless Integration with Industrial IoT Platforms

Avassa is designed to work seamlessly alongside your existing industrial IoT platforms and infrastructure. With features like automatic discovery of devices—including cameras and GPUs—and intelligent application placement based on hardware availability, Avassa fits naturally into modern manufacturing environments. Our platform provides a comprehensive overview of which industrial IoT applications are running at which locations, with built-in edge-native monitoring and observability. Whether you’re deploying advanced analytics, vision processing, or process automation, Avassa makes industrial edge computing easy to adopt and scale—without reworking your entire tech stack.

- Automatic discovery of devices such as cameras or GPUs

- Automated placement of applications based on device and GPU availability

- Comprehensive overview and control of which applications run in which on-site location

- Edge-native monitoring and observability

Edge Computing Use Cases in Manufacturing

- Predictive Maintenance and Machine Monitoring: Avassa can be used to deploy and manage applications that monitor the health and performance of manufacturing equipment across various locations. These industrial IoT applications can analyze data locally to predict maintenance needs, reducing downtime and extending the lifespan of machinery.

- Quality Control and Inspection: The industrial edge platform can support applications that perform real-time quality checks and inspections on the production line. By processing data on-site, manufacturers can quickly identify and address quality issues, ensuring product standards are consistently met.

- Supply Chain and Inventory Optimization: Avassa can manage applications that track and optimize inventory levels and supply chain processes across multiple manufacturing sites. Local data processing allows for real-time responses to inventory changes, helping to avoid stock outs or excess inventory and improving overall supply chain efficiency.

- Energy Management and Operational Efficiency: The IoT edge platform can be used to control and monitor applications that manage energy usage and other resources in manufacturing facilities. By processing this information locally, facilities can optimize energy consumption and operational efficiency, leading to cost savings and reduced environmental impact.

- Safety and Compliance Monitoring: Avassa can deploy applications that continuously monitor safety conditions and compliance with regulatory standards across manufacturing sites. Local data processing enables immediate responses to potential safety hazards or compliance issues, enhancing worker safety and regulatory adherence.

Industrial Leaders Choose Avassa for Industrial Edge

Frequently Asked Questions

Reach out

Interested in learning more about our technology?

Send us a message and we’ll let you know how we can help.